Vancouver, British Columbia--(Newsfile Corp. - October 15, 2024) - Canter Resources Corp. (CSE: CRC) (OTC Pink: CNRCF) (FSE: 601) ("Canter" or the "Company") is pleased to announce promising brine assay results from Phase II Geoprobe drilling and provide a recap summary for the 20 total shallow holes completed at its Columbus Lithium-Boron Project near Tonopah, Nevada. With consistent lithium and boron concentrations identified across a widespread area, these results strengthen the Project's potential for significant lithium-boron brine development. Pending solid sediment assays, expected in mid-Q4, will contribute to an updated 3D model that will guide Phase III exploration plans.

Highlights and Key Takeaways from Phased Shallow Drilling to-date

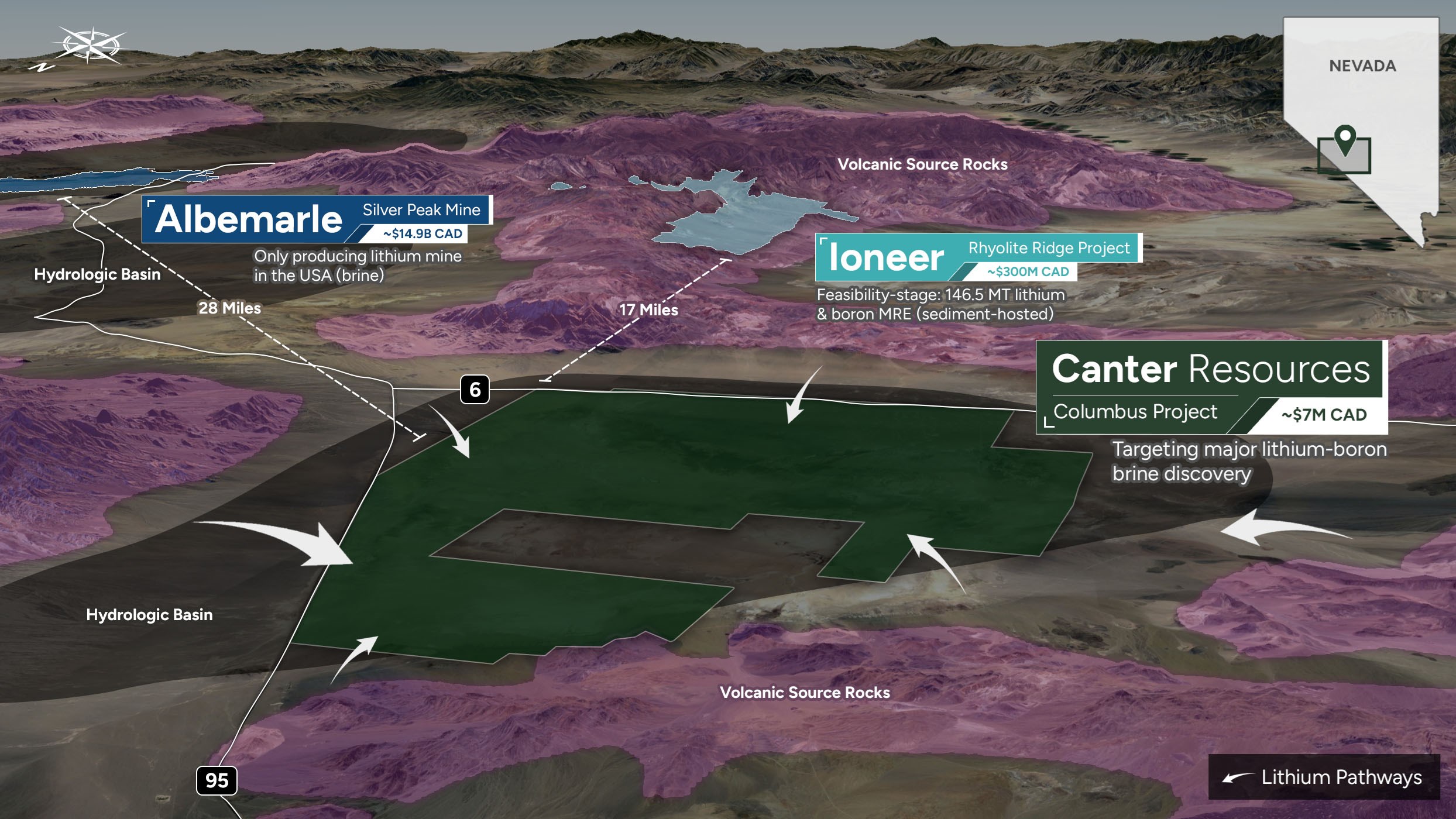

The Company's phased shallow drilling programs have delivered compelling evidence of the Columbus Basin's ability to generate the same lithium-boron commodity mix in brines as are seen at Ioneer's (~CAD$300M market capitalization) nearby Rhyolite Ridge deposit in sediments, which shares volcanic source rocks with the Columbus basin (see Figure 1).

-

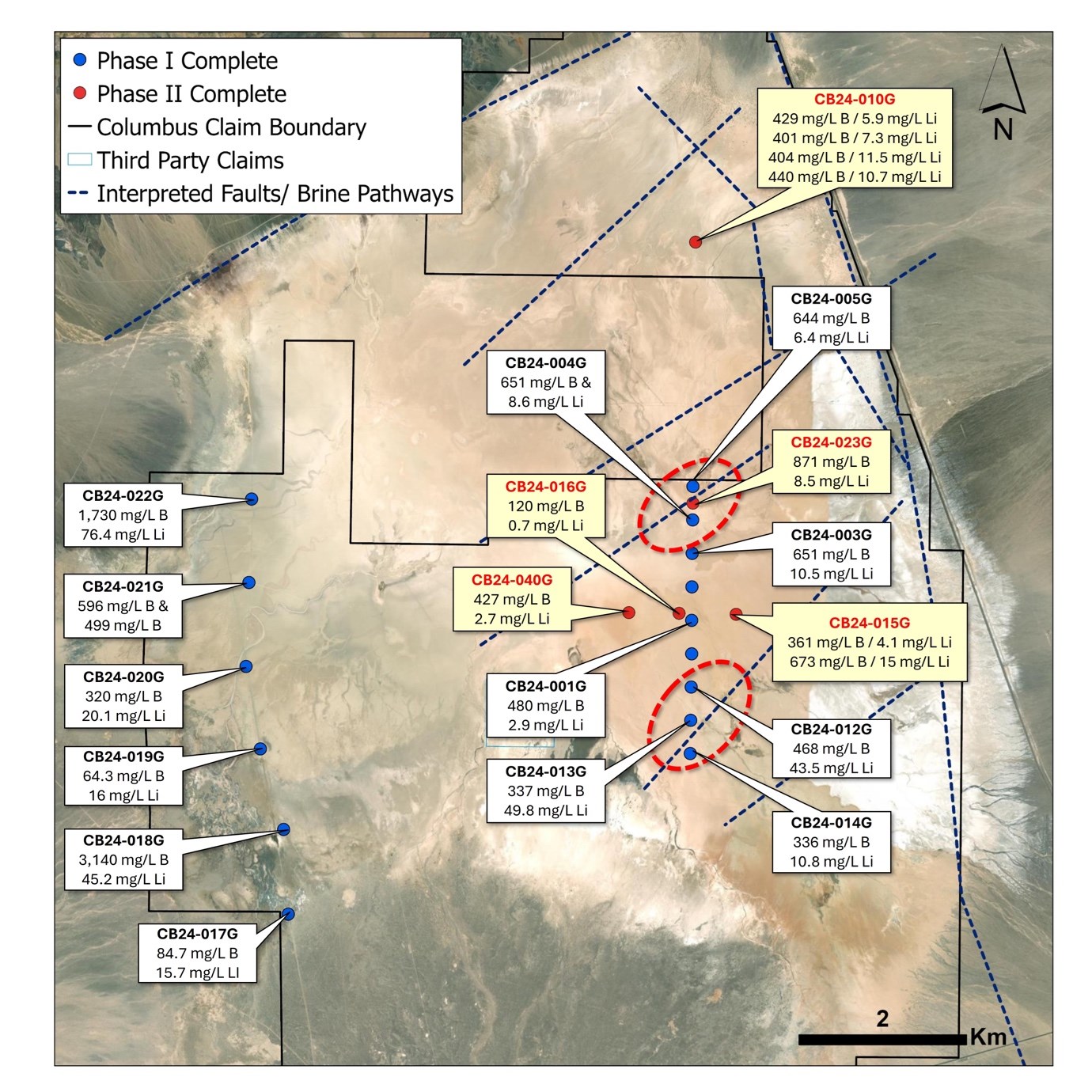

Highest Boron Concentration: Phase II infill drill hole (CB24-023G) returned 871 mg/L boron (total) and the highest dissolved boron concentration from Canter's drilling to-date (820 mg/L), providing further evidence of significant boron concentrations with increasing grades at depth (see Table 1 and Figure 2).

-

Lithium Mineralization: Phase II results (up to 15 mg/L) continue to demonstrate the consistent widespread anomalous lithium mineralization in brines from shallow drilling to-date with several >40 mg/L samples and a peak value of 76.4 mg/L (upper ~30 metres). In Clayton Valley (host to Albermarle's Silver Peak lithium brine operation), historical data shows lithium concentrations increase with depth-from 29 ppm at 53 meters to 283 ppm at 218 meters.1 Collectively, Phase I and II results reveal widespread anomalous lithium concentrations in shallow brines, significantly extending the lithium-bearing footprint. The results underscore the continuity of mineralization, supporting the Company's hypothesis that higher lithium grades will be encountered at depth as exploration continues.

-

Higher-Grade Potential at Depth: Based on structural similarities to Clayton Valley, the Columbus Basin shows significant potential for higher-grade lithium brines at depth. With shallow zones already returning substantial anomalous values, the structural traps and closed hydrological system observed in the basin indicate that deeper aquifers could host even more concentrated lithium brines, similar to patterns seen in mature lithium-producing regions.

-

Consistent Brine Generation Over Significant Footprint: Phase II drill hole CB24-010G returned >400 mg/L boron and up to 11.7 mg/L lithium approximately three (3) kilometres to the north of Phase I locations, extending the near-surface brine generation footprint significantly (see Figure 2).

Geophysical data from HSAMT and seismic surveys has been instrumental in guiding the Company's exploration strategy, highlighting structural traps and low-resistivity zones, which are favourable indicators of brine accumulation. This data will be further validated in Phase III, targeting deeper aquifers for lithium-rich brine zones.

"Our phased shallow drilling campaigns have confirmed the presence of widespread lithium and boron mineralization within shallow aquifers, and we are increasingly confident that subsequent deeper drilling will unlock the higher-grade potential for multiple strategic and critical minerals at Columbus," commented Canter CEO, Joness Lang. "The structural and geochemical similarities to both Clayton Valley and Rhyolite Ridge, support our exploration model and our low-cost shallow drilling has helped build the foundation to make a major discovery at Columbus."

Figure 1: Map showing Columbus in the foreground and proximity to Silver Peak and Rhyolite Ridge

Figure 2: Plan view map highlighting widespread near-surface mineralization at Columbus

Technical Observations and Interpretations

Brine development is extensive across the basin, to the present day, with very favourable conditions for evapo-concentration and retention of generated brines; even in the current time period.

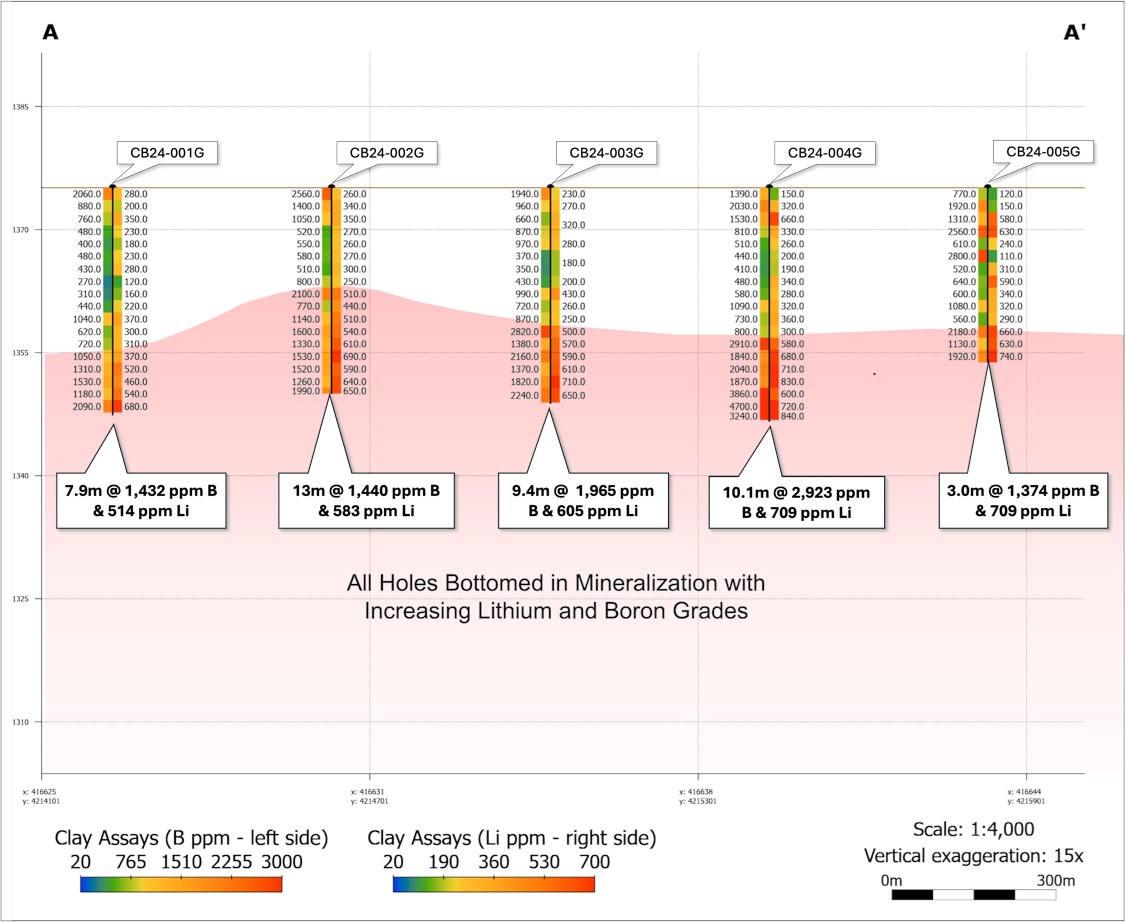

Brine development is closely associated with areas of elevated lithium content in sediments. Previous solid assays confirmed high lithium values in direct contact with groundwater, suggesting that lithium is being mobilized from solid sources into brines. This natural leaching process is key to the formation of economically viable lithium brines at Columbus.

Figure 3: Increasing lithium and boron grades in solid sediment samples (Phase I) in near-surface brine generation layers provide a source for further brine-enrichment below (Phase II solid samples pending).

Substantial boron enriched brines that are laterally extensive. Not only is boron economically of interest, but the boron enrichment also indicates that elements (other than sodium chloride (NaCl)) are collecting in solution. This has positive implications for potential further lithium concentrations in the basin.

There appears to be differential lithium grades in solution, depending on location. This suggests that either lithium is dissolving preferentially in certain areas, or that there are longer residence times of the solution in certain areas. The Company's technical team is completing further analysis of the geochemistry in relation to the known and interpreted faults as part of its 3D model updating.

Halite beds have been intersected across substantial lateral distances, suggesting the presence of large-scale mature paleo playas and extended periods of equilibrium allowing for the development of fully saturated brines. The brines generated in these periods would have been extremely high TDS (total dissolved solids) and likely migrated into structural reservoirs, where they could still be present.

Potassium and Magnesium: Potassium values in Phase II remained consistent with values across the aggregate shallow program typically reaching concentrations in the 3,000 mg/L range with a peak of 5,870 mg/L. Preliminary multi-element analysis showed magnesium concentrations below detection limits, which bodes well for future direct lithium extraction (DLE) considerations.

Preliminary Multi-Element Analysis: High concentrations of sodium, potassium, boron, chloride and carbonate along with demonstrated halite beds profiles similarly (aside from not encountering trona beds to-date) to historical shallow geochemical results reported at Searles Lake, which has been a significant producer of soda ash, borax and boric acid for more than a century (Searles Valley Minerals acquired by Nirma Limited (USD$300M) in 2007).2

Summary

The results from Phase II drilling further confirm the presence of widespread lithium and boron brine mineralization within the shallow aquifers of Columbus Basin. With geophysical data pointing to significant potential at depth, Canter Resources is well-positioned to advance toward deeper targets in its Phase III exploration, where higher-grade brines are expected. The Company remains committed to unlocking the full resource potential of this strategic lithium-boron project.

Table 1: Assay Results from Phased 2024 Shallow Drilling

| Sample ID | Sample Depth (m) |

Total Sample Volume (mL) |

B Total mg/L |

B Dissolved mg/L |

Li Total mg/L |

Li Dissolved mg/L |

K Total mg/L |

K Dissolved mg/L |

Na Total % |

Na Dissolved % |

| CB24-010G-45 | 13.7 | 350.0 | 429.0 | 395.0 | 5.9 | 5.2 | 1870.0 | 1700.0 | NT | NT |

| CB24-010G-50 | 15.2 | 350.0 | 401.0 | 394.0 | 7.3 | 7.3 | 1880.0 | 1840.0 | NT | NT |

| CB24-010G-75 | 22.9 | 350.0 | 404.0 | 389.0 | 11.5 | 7.0 | 2060.0 | 1890.0 | NT | NT |

| CB24-010G-100 | 30.5 | 350.0 | 440.0 | 381.0 | 10.7 | 5.7 | 1520.0 | 1250.0 | NT | NT |

| CB24-015G-40 | 12.2 | 350.0 | 361.0 | 381.0 | 4.1 | 4.2 | 3250.0 | 3470.0 | NT | NT |

| CB24-015G-100 | 30.5 | 350.0 | 673.0 | 352.0 | 15.0 | 2.5 | 3560.0 | 2650.0 | NT | NT |

| CB24-016G-4 | 1.2 | 350.0 | 427.0 | 422.0 | 2.7 | 2.2 | 3400.0 | 3160.0 | NT | NT |

| CB24-023G-50 | 15.2 | 1500.0 | 871.0 | 820.0 | 8.5 | 7.5 | 2620.0 | 2400.0 | 8.8 | 8.3 |

| CB24-040G-99 | 30.2 | 1500.0 | 120.0 | 113.0 | 0.7 | 0.6 | 725.0 | 707.0 | 2.6 | 2.5 |

| Results below previously reported (see press release July 2, 2024) | ||||||||||

| CB24-011G-91 | 27.7 | 350.0 | 480.0 | 520.0 | 24.0 | 8.3 | 3400.0 | 3000.0 | NT | NT |

| CB24-002G-5.5 | 1.7 | 350.0 | 19.0 | 20.0 | <2.5 | <2.5 | 160.0 | 160.0 | NT | NT |

| CB24-003G-37.5 | 11.4 | 350.0 | 393.0 | 418.0 | 1.4 | 1.1 | 3330.0 | 3650.0 | NT | NT |

| CB24-003G-53 | 16.2 | 350.0 | 383.0 | 387.0 | 7.7 | 4.3 | 3640.0 | 3670.0 | NT | NT |

| CB24-003G-86 | 26.2 | 350.0 | 651.0 | 584.0 | 10.5 | 8.9 | 2850.0 | 2350.0 | NT | NT |

| CB24-004G-45 | 13.7 | 350.0 | 397.0 | 408.0 | 2.8 | 2.5 | 3720.0 | 2920.0 | NT | NT |

| CB24-004G-93 | 28.4 | 350.0 | 651.0 | 655.0 | 8.6 | 8.4 | 2990.0 | 2720.0 | NT | NT |

| CB24-005G-60 | 18.3 | 350.0 | 644.0 | 645.0 | 6.4 | 5.7 | 3200.0 | 2620.0 | NT | NT |

| CB24-017G-12.5 | 3.8 | 350.0 | 84.7 | 61.2 | 15.7 | <4.0 | 1020.0 | 410.0 | NT | NT |

| CB24-018G-29 | 8.8 | 350.0 | 3140.0 | 132.0 | 45.2 | 1.0 | 3730.0 | 93.3 | NT | NT |

| CB24-019G-70 | 21.3 | 350.0 | 64.3 | 44.0 | 16.0 | 1.0 | 913.0 | 305.0 | NT | NT |

| CB24-020G-72.5 | 22.1 | 350.0 | 320.0 | 270.0 | 20.1 | <4.0 | 1450.0 | 754.0 | NT | NT |

| CB24-021G-10x | 3.0 | 350.0 | 596.0 | 581.0 | <4.0 | <4.0 | 1860.0 | 1640.0 | NT | NT |

| CB24-021G-42.5 | 13.0 | 350.0 | 499.0 | 478.0 | 4.2 | <4.0 | 1870.0 | 1600.0 | NT | NT |

| CB24-022G-77.5 | 23.6 | 350.0 | 1730.0 | 92.8 | 76.4 | <4.0 | 7950.0 | 291.0 | NT | NT |

| Results below previously reported (see press release June 3, 2024) | ||||||||||

| CB24-014G-33 | 10.1 | 350.0 | 336.0 | 331.0 | 10.8 | 2.5 | 4250.0 | 3820.0 | NT | NT |

| CB24-014G-54 | 16.5 | 350.0 | 315.0 | 303.0 | 4.4 | 4.0 | 3340.0 | 3090.0 | NT | NT |

| CB24-013G-30 | 9.1 | 350.0 | 331.0 | 316.0 | 2.5 | 2.1 | 3860.0 | 3750.0 | NT | NT |

| CB24-013G-48 | 14.6 | 350.0 | 337.0 | 312.0 | 49.8 | 2.3 | 5630.0 | 3510.0 | NT | NT |

| CB24-012G-35 | 10.7 | 350.0 | 385.0 | 375.0 | 2.7 | ND | 4410.0 | 4110.0 | NT | NT |

| CB24-012G-57 | 17.4 | 350.0 | 454.0 | 386.0 | 43.5 | 2.2 | 5870.0 | 3500.0 | NT | NT |

| CB24-012G-62.5x | 19.1 | 350.0 | 468.0 | 427.0 | 15.3 | 2.3 | 4410.0 | 4090.0 | NT | NT |

| CB24-011G-40 | 12.2 | 350.0 | 446.0 | 463.0 | 41.2 | 2.5 | 5030.0 | 4070.0 | NT | NT |

| CB24-011G-2.7x | 0.8 | 350.0 | 508.0 | 420.0 | 2.8 | ND | 4110.0 | 3270.0 | NT | NT |

| CB24-011G-18 | 5.5 | 350.0 | 425.0 | 409.0 | ND | ND | 3380.0 | 3210.0 | NT | NT |

| CB24-001G-35 | 10.7 | 350.0 | 480.0 | 458.0 | 2.8 | 2.4 | 4130.0 | 3850.0 | NT | NT |

Note 1: Differences in detection limits are due to the Dilution Factor (DF) being used.

Note 2: (x) = Duplicate

Note 3: Total solids encompass all the solid matter, both dissolved and suspended, found in water, including organic and inorganic substances. In contrast, dissolved solids refer specifically to the portion of total solids that are soluble in water, such as salts, minerals, and some organic materials, passing through a filter and remaining in solution.

Note 4: (NT) = Not Tested, specific samples were analyzed for more analytes due to their proximity to certain geological features, i.e. halite beds

For more information about boron and lithium, please visit the Company's Boron 101 and Lithium 101 pages on the website.

Disclaimer: Mineralization at nearby or adjacent projects is not necessarily indicative of mineralization at the Company's Columbus Project.

Qualified Person (QP)

The technical information contained in this news release was reviewed and approved by Eric Saderholm P.Geo, Director and Technical Advisor of Canter Resources, a Qualified Person (QP), as defined under National Instrument 43- 101 - Standards of Disclosure for Mineral Projects.

Quality Assurance / Quality Control (QA/QC)

In a continued commitment to ensuring the highest standards of data accuracy and reliability, the Company has implemented a rigorous quality assurance and quality control (QA/QC) protocol for both groundwater and sediment sampling and analysis. This initiative is designed to enhance the precision and credibility of sampling techniques and assay results.

Upon reaching the target lithology depth during drilling, groundwater sampling is initiated with care to avoid surpassing the designated zone. Utilizing a drive-point screen sampler or mechanical bailer, groundwater is extracted to ensure a clean and uncontaminated collection process. Initial purging is conducted, and a Myron Ultrameter II is used to measure general parameters, such as temperature, pH, total dissolved solids (TDS), specific conductivity, and oxidation-reduction potential (ORP). For wet samples, a minimum 350 mL of groundwater is collected for comprehensive analysis, with all samples handled under strict chain of custody (COC) protocols and stored under optimal conditions until delivery to Western Environmental Testing (WETLAB).

About Canter Resources Corp.

Canter Resources Corp. is a junior mineral exploration company advancing the Columbus Lithium-Boron Project in Nevada, USA and the Beaver Creek Lithium Property in Montana, USA. The Company is completing a phased drilling approach at Columbus to test highly prospective brine targets at varying depths for lithium-boron enrichment and plans to leverage the Company's critical metals targeting database to generate a portfolio of high-quality projects with the aim of defining mineral resources that support the technology and dNoteomestic clean energy supply chains in North America.

For further information contact:

Joness Lang

Chief Executive Officer

Canter Resources Corp.

Tel: 778.382.1193

For investor inquiries contact:

Kristina Pillon, High Tide Consulting Corp.

Tel: 604.908.1695

The Canadian Securities Exchange has neither approved nor disapproved the contents of this news release. The Canadian Securities Exchange does not accept responsibility for the adequacy or accuracy of this news release.

1 Davis, J., Friedman, I., & Gleason, J. (n.d.). ORIGIN OF THE LITHIUM-RICH BRINE, CLAYTON VALLEY, NEVADA Chapter L.

2 George I. Smith, Subsurface Stratigraphy and Geochemistry of Late Quaternary Evaporites, Searles Lake, California, Geological Survey Professional Paper 1043.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/226504